|

|

Product Description Product Description

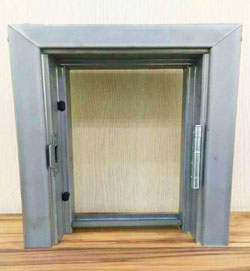

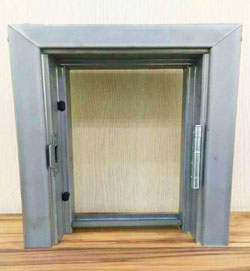

Our company manufactures a comprehensive range of high quality metal door & window frames.

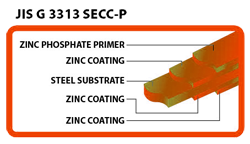

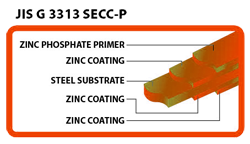

Materials used are certified Electro-Galvanised Steel Strips conforming to all metal frames.

State-of-the-art Roll-Forming machinery and up-to-date technilogy are employed in the manufacturing process;

combined with professional workmanship, comprehensive technial and stringent quality control,

every metal frame built is truly a craftmanship of superior quality.

All HAI KANG STEEL metal frames, bearing the HAI KANG STEEL hallmark of quality and reliability, are fully ensured of all the following economical, constructional & engineering advantages:

- higher cost effectiveness or more economical than timber frames

- environment friendly, 100% recyclable

- will not wrap, shrink, distort, rot or be damaged by pest attacks

- fast & simple installation

- lightweight & easy transportation

- aesthetical with built in architraves hinges

- come with hinges, striker plate & lock pocket and shock absorbing buffers

- forming an integral part of the wall & enhance its structural strength

- provide a smooth, clean & neat finish to brickwork

- no additional surface preparation & readily paintable

(A) Hai Kang Steel KD-118 Metal Door Frame Knocked-Down System

(Patent Registration No: PI9700638)

Hai Lang Steel KD-118 Knocked-Down System Metal Door Frame is a patented innovation with advantages not found in the conventional built-up system to fulfill the specific needs of both the retailers and builders.

(B) Hai Kang Steel BU-118 Metal Door Frame Built-Up System

BU-118 Built-Up System Metal Door Frame is an alternative system available for the choice of builders or any other users to suit their constructional needs.

Technical Specification Technical Specification

Material

Hot-Dipped Galvanized, Electro Galvanized Steel

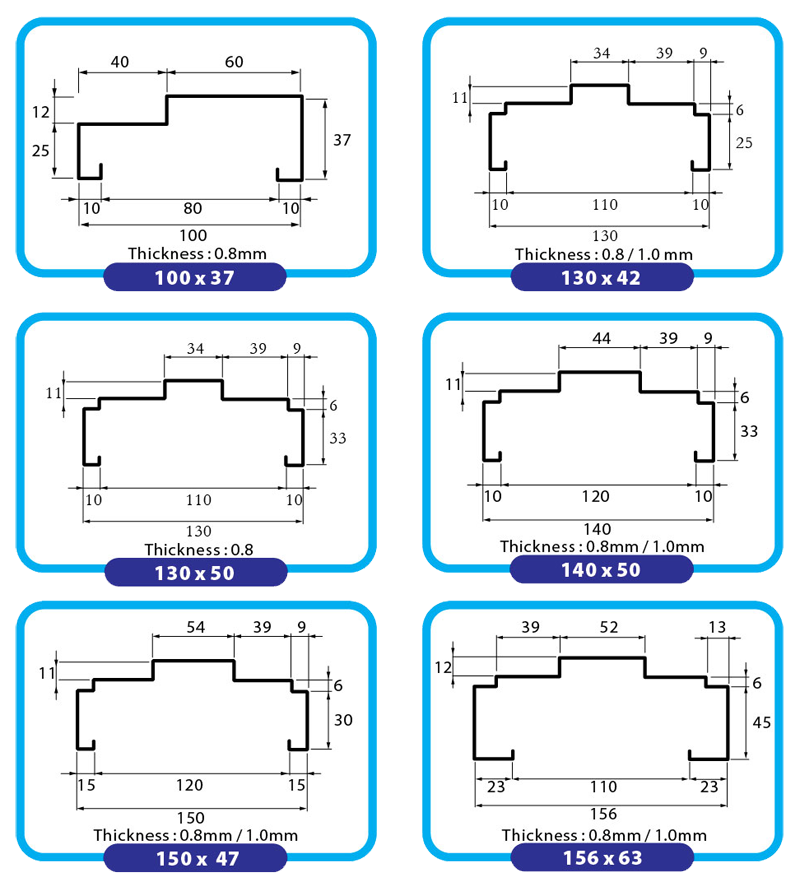

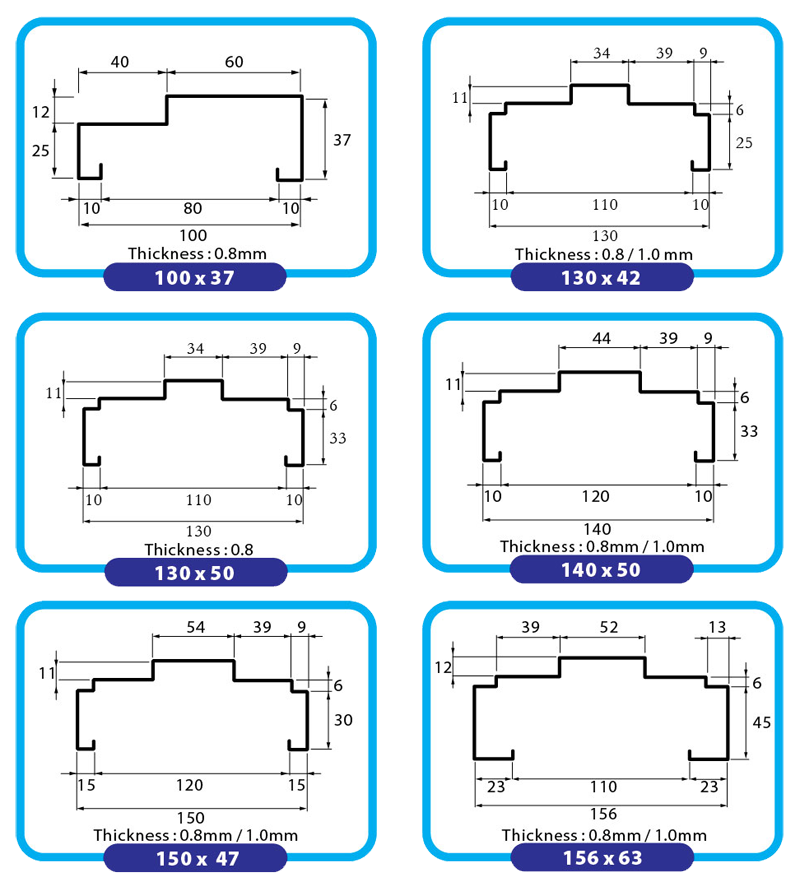

Profile

Head & jamb exclusive 14-fold (130WA, 140WA, 150WA, 156WA) /

8-fold rollformed profile (100 std)

Corners

Tagged, mitred, welded & treated / Patented Knocked-Down (KD-118) System |

|

* The weight and height tolerance within +/- 2mm

|